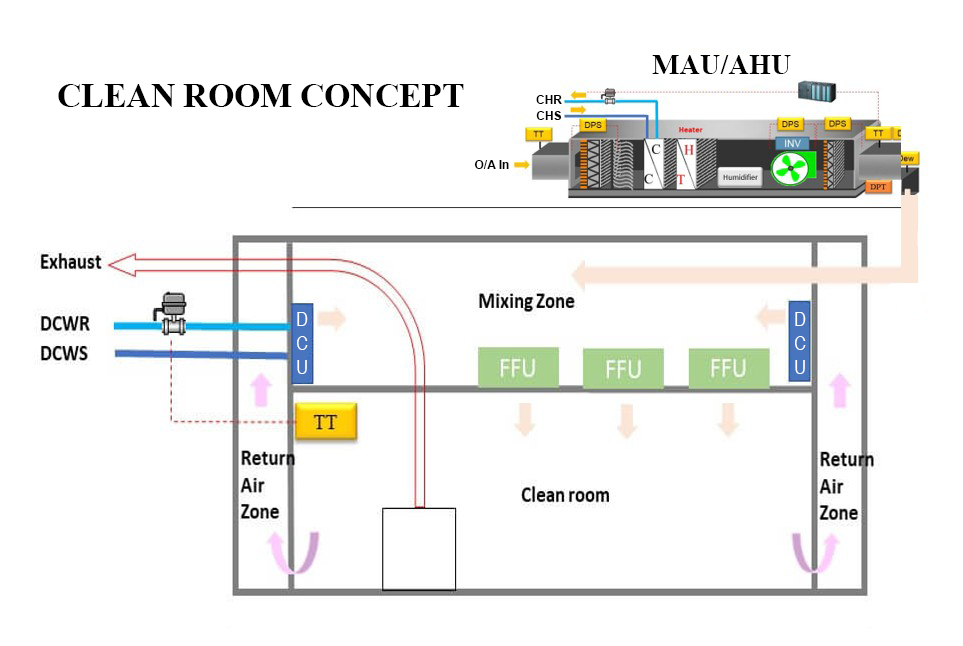

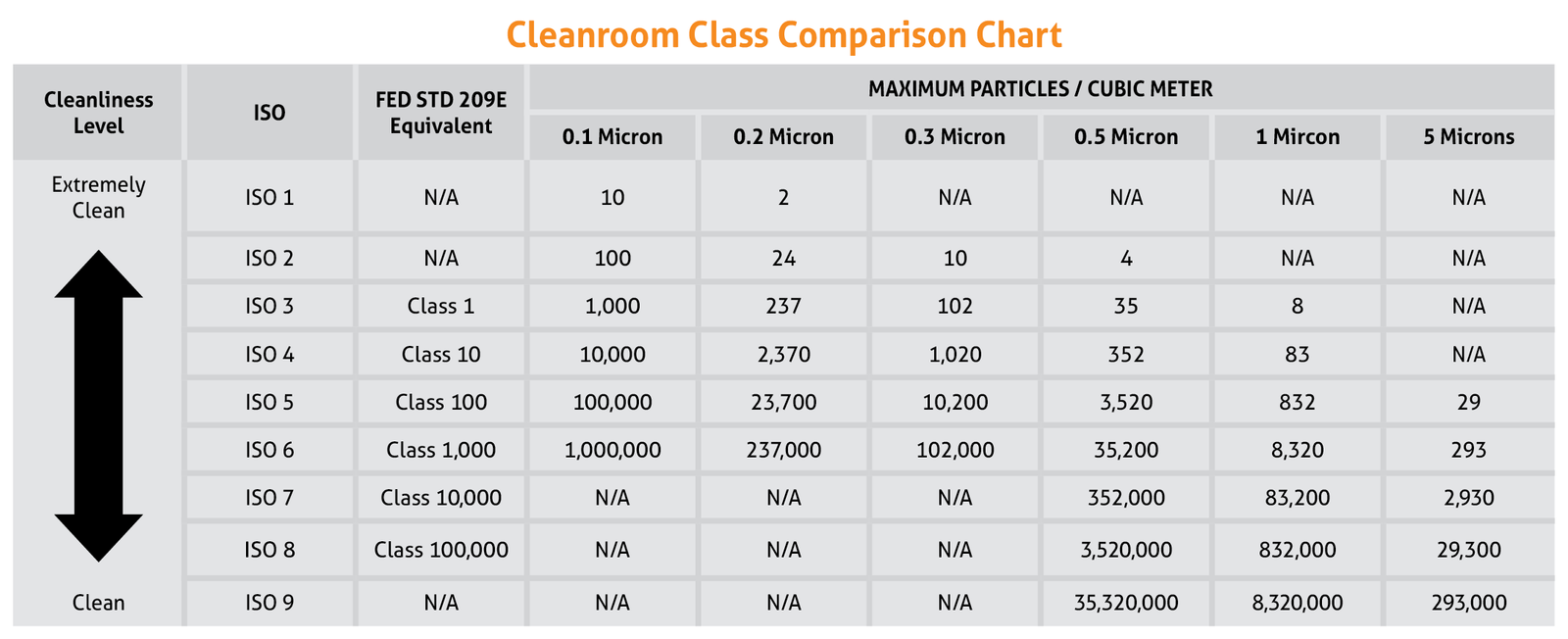

A cleanroom is a controlled environment system where pollutants like dust, airborne microbes, and aerosol particles are filtered out in order to provide the cleanest area possible. Clean room Service plays a vital role in maintaining the desired cleanliness, temperature, humidity, pressure control, and air quality levels required for the specific clean room application. Xuan-Tong (BD) Co., Ltd. can design a clean room system for you as per the ISO Guidelines and industry standard, based on your special requirements.

By offering a wide range of specialized products and equipment, Clean Room Service ensures optimal cleanliness, safety, and efficiency across various industries, chemical industries, optical industries, including pharmaceuticals, electronics, healthcare, IT room, data center room, and research laboratories.

XTBD also has optimistic, economical, and customizable design, installation, and maintenance services as per client’s requirements.