PCW is a compact, skid-mounted system that circulates process water at a consistent temperature and pressure to the application’s point of use and back, allowing for more efficient and stable use of water-cooled machines, equipment, and instruments. Many process tools, particularly in the semiconductor and solar industries, generate heat during their use. This heat must be removed from the process on a continuous basis during tool operation.

Xuan-Tong BD CO., LTD., offers custom design and engineering of state-of-the-art turnkey industrial process system.

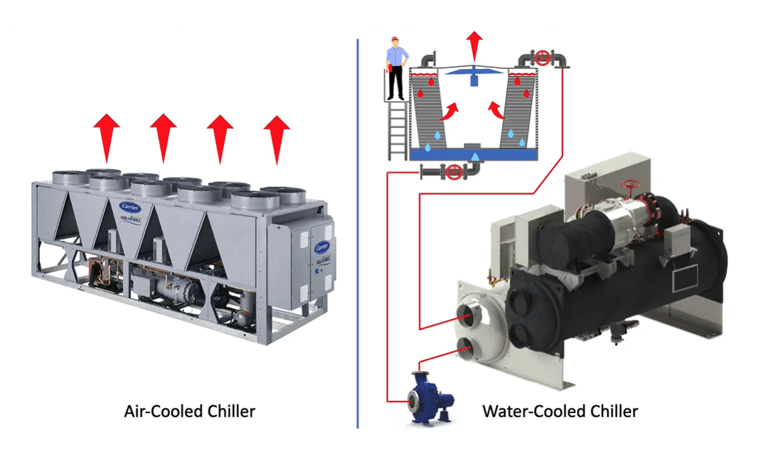

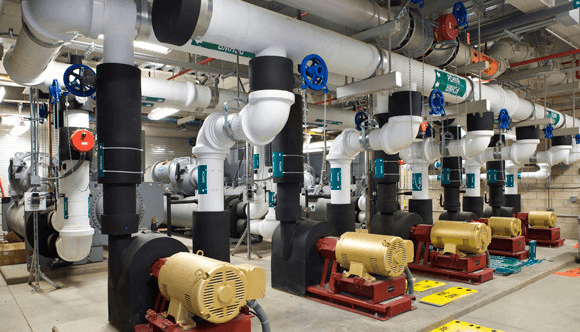

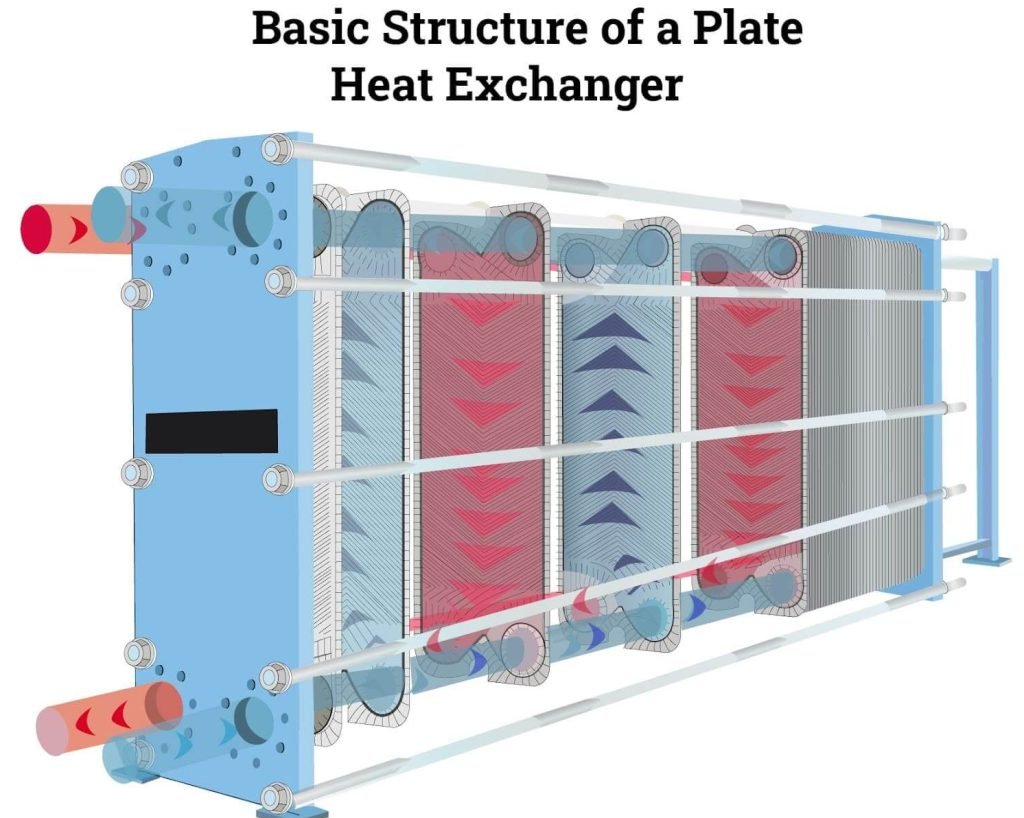

Process Cooling Water System consist of several key components that work together to provide precise temperature control and cooling for industrial processes. Here are the main components typically found in PCW system:

Process Cooling Water System consist of several key components that work together to provide precise temperature control and cooling for industrial processes. Here are the main components typically found in PCW system: